D&W builds the very equipment that powers liquid food production. Our custom-built machinery ensures precision, efficiency, and quality in every drop.

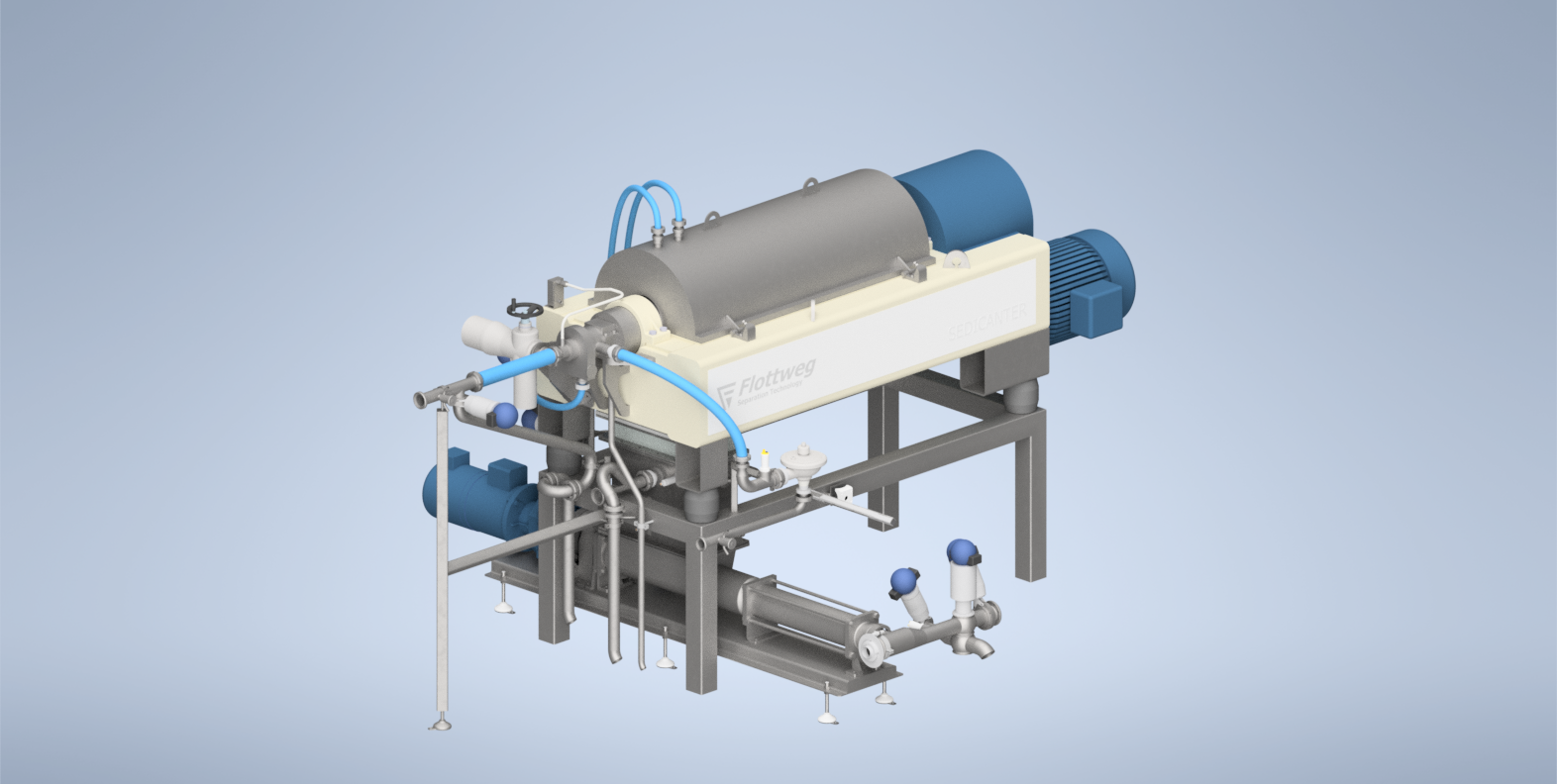

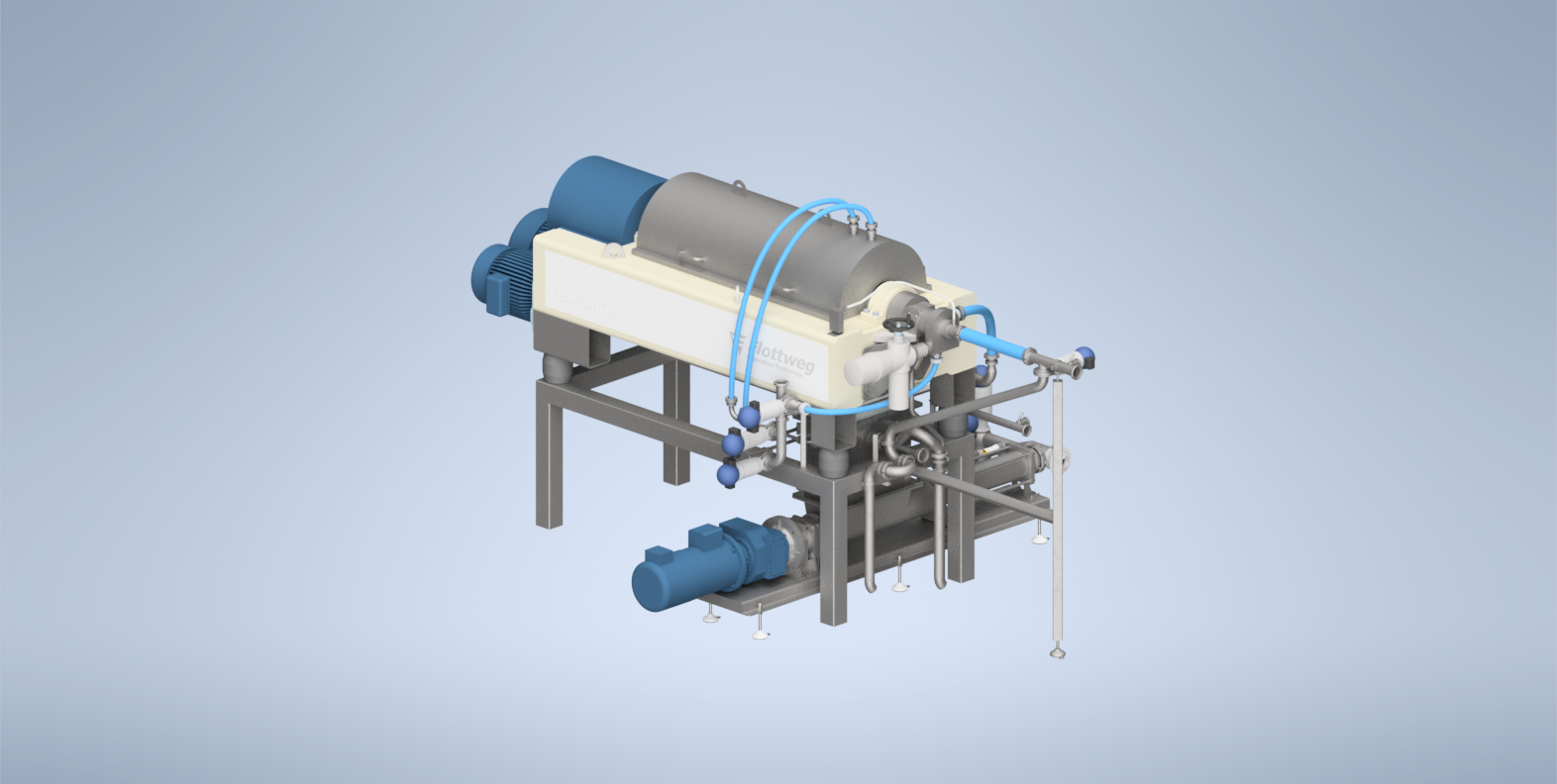

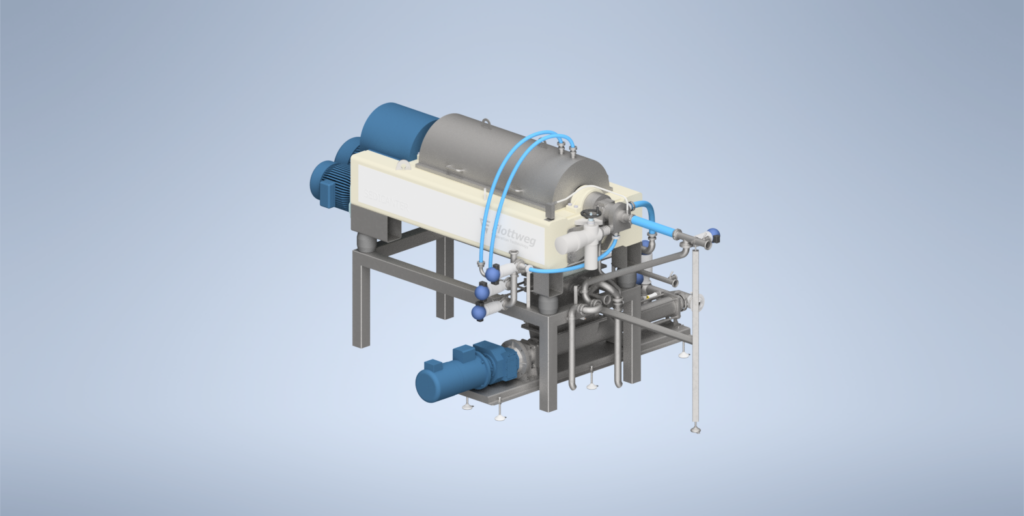

DecantConnect System

Streamlining solid-liquid separation for high solid-load applications

Description

Application

In the dynamic world of the food industry, sustainability is of the utmost importance. Decanters play an important role in this by, for example, facilitating the extraction of proteins from various sources. Notable applications include extracting proteins from brewers’ grains, a by-product of brewing, and isolating the solid protein fraction from insects. These protein-rich extracts are valuable ingredients for a variety of food products. At D&W, we use decanter technology – often from Flottweg – to optimise various processes and thus contribute to a sustainable future.

Concept

Flottweg decanter centrifuges are a continuous method for separating liquids and solids. The separation takes place by means of increased g-forces whereby differences in densities are used. This makes separation possible between a liquid and a solid (decanter), or between two liquids and a solid (tricanter®). There is also a special version for separating and dewatering soft components such as proteins, yeasts and algae (sedicanter®).

Flottweg decanters can be made hygienically and are therefore often used in the food industry. Decanters are made with capacities ranging from several hundred litres/hour to many m3/hour. Each application has its own version for optimum separation and reliable production. Each Flottweg decanter is specifically designed and produced for this purpose.

Working principle

In a Flottweg decanter, the flow to be separated is continuously fed into a rotating bowl. This bowl rotates at speeds of several thousand rotations per minute, which can achieve g-forces of between 1,000-10,000g. This causes the solids to sit against the bowl and the liquid to become more centred. The solids are then transported out of the bowl using a screw. The liquids are led out of the bowl via a free overflow or by means of an adjustable impeller.

The innovative torque-controlled Simp-drive® control of the motors ensures a continuous, constant quality of the product. D&W provides these decanters with the necessary process functionality for the constant and safe supply of product as well as the discharge of the solid and liquid fraction. Integrated CIP functionality ensures problem-free and automated cleaning of the installation after production.

HMI panel

The HMI panel provides many

possibilities to control the separation.

Details

Base unit

This unit consists of a base module which is positioned on a fixed or frame. The base module consists of, among other things:

- A decanter centrifuge

- A control panel with HMI en PLC

- Discharge functionality for both the liquid and solidstream

- CIP functionality

Automation

Flottweg decanters are supplied with a stainless steel control cabinet equipped with the easy to operate HMI and Siemens PLC. By means of communication exchange, the control cabinet is integrated by D&W in a main control system.

Optional

- Automated CIP cleaning

- Automated impeller

- Various materials possible (duplex, super duplex and hastelloy)

- ATEX excecution

Options not included

Data

Technical

Consumption

Curious about what we can do for you?

Then contact us now!