D&W builds the very equipment that powers liquid food production. Our custom-built machinery ensures precision, efficiency, and quality in every drop.

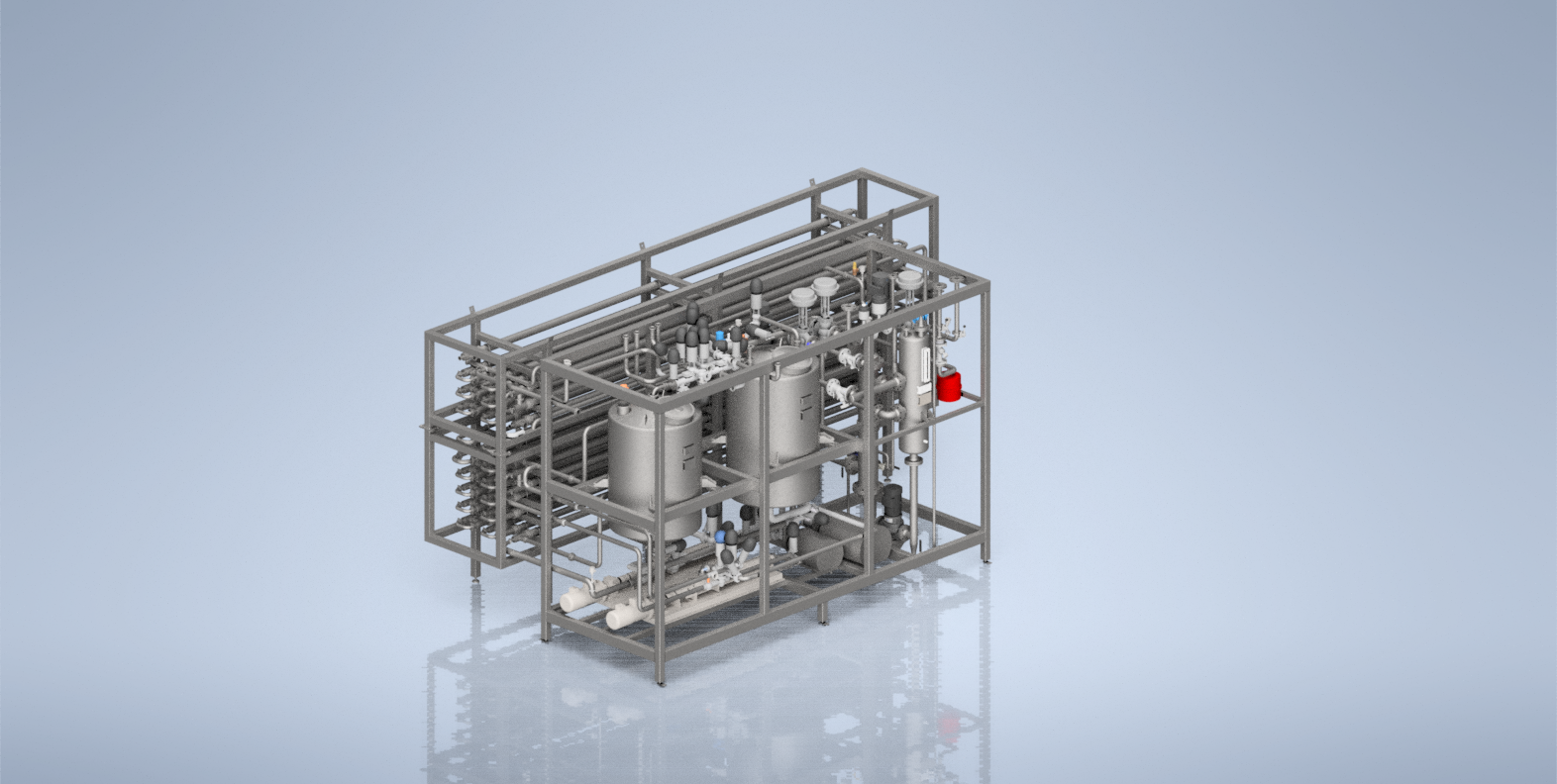

PasteurFlow System

Continuous quality and safety in food processing

Description

Application

Continuous pasteurizers using tube heat exchangers play a central role in the food processing industry, particularly in the treatment of low to medium viscosity products. These systems are widely used in the pasteurization of juices, dairy products and various liquid foods. Continuous pasteurization ensures that the product is gently heated, preventing burns against the wall and, for example, denaturation of proteins, while eliminating harmful bacteria and enzymes. At D&W, we emphasize the crucial role of continuous pasteurization in improving food safety and delivering high-quality products to consumers.

Concept

The concept behind continuous pasteurizers using shell-and-tube heat exchangers is focused on gentle heating to maintain product quality and safety. The design of the heat exchanger promotes efficient heat transfer by exposing the product to minimal harsh conditions. The product flows through the tubes while the heating medium circulates in the ‘shell’, which provides a controlled heating process. This gentle heating method prevents the product from burning against the wall and minimizes denaturation of sensitive components, thus preserving the natural flavor and nutritional value of the product.

Working principle

Our pasteurisation systems usually consist of a balance tank in which the raw product is dosed. From this balance tank, the liquid is sent through a series of heat exchangers under exact conditions. This is often a preheating step, a pasteurisation step, a holding step and a cooling step. In order to increase the energy efficiency of our systems, a regeneration step can optionally be chosen in which heat from the cooling path is used in the preheating step. In each step, we monitor the temperature accurately and automatically adjust where necessary. The product is pumped through our pasteurisation systems by means of low-shear pumps that ensure minimal product damage and a continuous flow. Another integrated component of these systems is the automatic Clean-in-Place (CIP) cleaning cycle. This automated cleaning process improves the hygiene of the system by efficiently cleaning and disinfecting the heat exchanger, which ensures optimal production times for these installations. Continuous pasteurizers with shell-and-tube heat exchangers are a testament to modern food processing technologies and ensure efficient and safe food production.

Heating

Depending on the food, we heat it in a controlled manner with hot water or steam.

Details

Base unit

This unit consists of a base module which is positioned on a fixed or frame. The base module consists of, among other things:

- A balance tank

- A shell-and-tube heat exchanger

- The required steam or hot water facilities

- The required CIP facilities

Automation

Our units are controlled by a Siemens PLC as standard. This is installed in a stainless steel control cabinet on the unit. On request, an Allen Bradley ControlLogix can also be applied. Operation is via an HMI panel mounted on the control cabinet. The HMI panel visualises a clear program with a large number of adjustable parameters and settings.

Optional

- Heating by electricity

- Booster pumps if necessary

- In-line dispersion pump

Options are not included

Data

Technical

Consumption

Curious about what we can do for you?

Then contact us now!