D&W builds the very equipment that powers liquid food production. Our custom-built machinery ensures precision, efficiency, and quality in every drop.

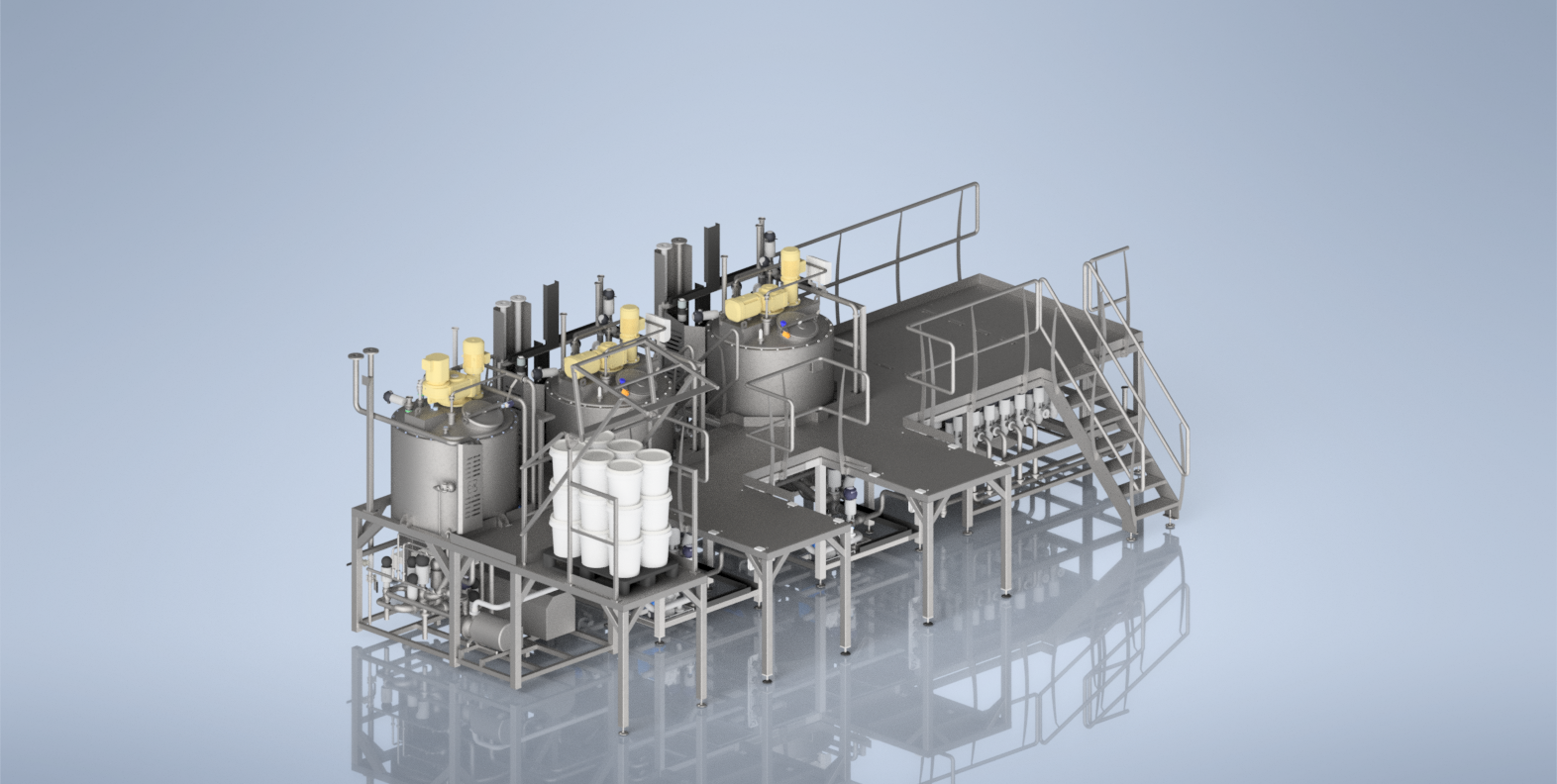

PasteurBatch System

Flexibility, safety and quality in food processing

Description

Application

Batch heating/pasteurization systems are an integral part of the food processing industry, especially when dealing with liquid foods. These systems are widely used in cooking sauces, pasteurizing juices and even blanching insects for various food products. Batch systems ensure that the liquid food is heated to precise temperatures and held for specific periods of time, effectively eliminating harmful microorganisms while preserving flavor and nutritional value. At D&W, we emphasize the importance of batch heating/pasteurization systems in improving food safety and delivering high-quality products to consumers.

Concept

The concept behind batch heating/pasteurization systems focuses on precision heating to ensure food safety and quality. Liquid foods are buffered in a controlled environment in a tank, precisely heated to the desired temperature and held for the required time. This process effectively pasteurizes the food, making it safe for consumption while preserving its natural flavor and nutritional composition. The concept is adaptable, allowing for variations based on specific requirements for heating sauces or blanching insects, for example, resulting in optimal processing for different food products.

Working principle

Our batch-continuous systems always consist of two or more production tanks. Each production tank is designed per application and, if necessary, equipped with the necessary agitators. Heat is then supplied via direct or indirect means, such as steam or hot water circulation. The temperature is precisely controlled to ensure an even heat distribution and thorough pasteurization. The duration of the heating is carefully controlled to achieve the intended safety and quality standards. After the pasteurization process, the product is pumped by means of specifically selected pumps and associated valve configurations. This operating principle guarantees that liquid foods, whether sauces or insect-based products, undergo a safe and controlled heating process that meets the required safety and taste parameters.

Agitators

For each application, we look at which agitators best suit the product and the process.

Details

Base unit

This unit consists of a base module which is positioned on a fixed or frame. The base module consists of, among other things:

- A fully stainless steel double-walled insulated cooking kettle

- One or more agitators depending on the application

- A heating circuit for pasteurization

- CIP functionality for cleaning.

- Various valves and instruments

Automation

Our units are controlled by a Siemens PLC as standard. This is installed in a stainless steel control cabinet on the unit. On request, an Allen Bradley ControlLogix can also be applied. Operation is via an HMI panel mounted on the control cabinet. The HMI panel visualises a clear program with a large number of adjustable parameters and settings.

Optional

- Standard trolley tipper for solid ingredients and standard trolley hatch

- Discharge pump including valve manifold

- Platform with tilting gate for dosing solid ingredients

- Vacuum cooling functionality

- In-line dispersing pump or agitator for reducing solid parts

- Electric heating instead of steam or hot water

Options are not included

Data

Technical

Consumption

Curious about what we can do for you?

Then contact us now!