D&W builds the very equipment that powers liquid food production. Our custom-built machinery ensures precision, efficiency, and quality in every drop.

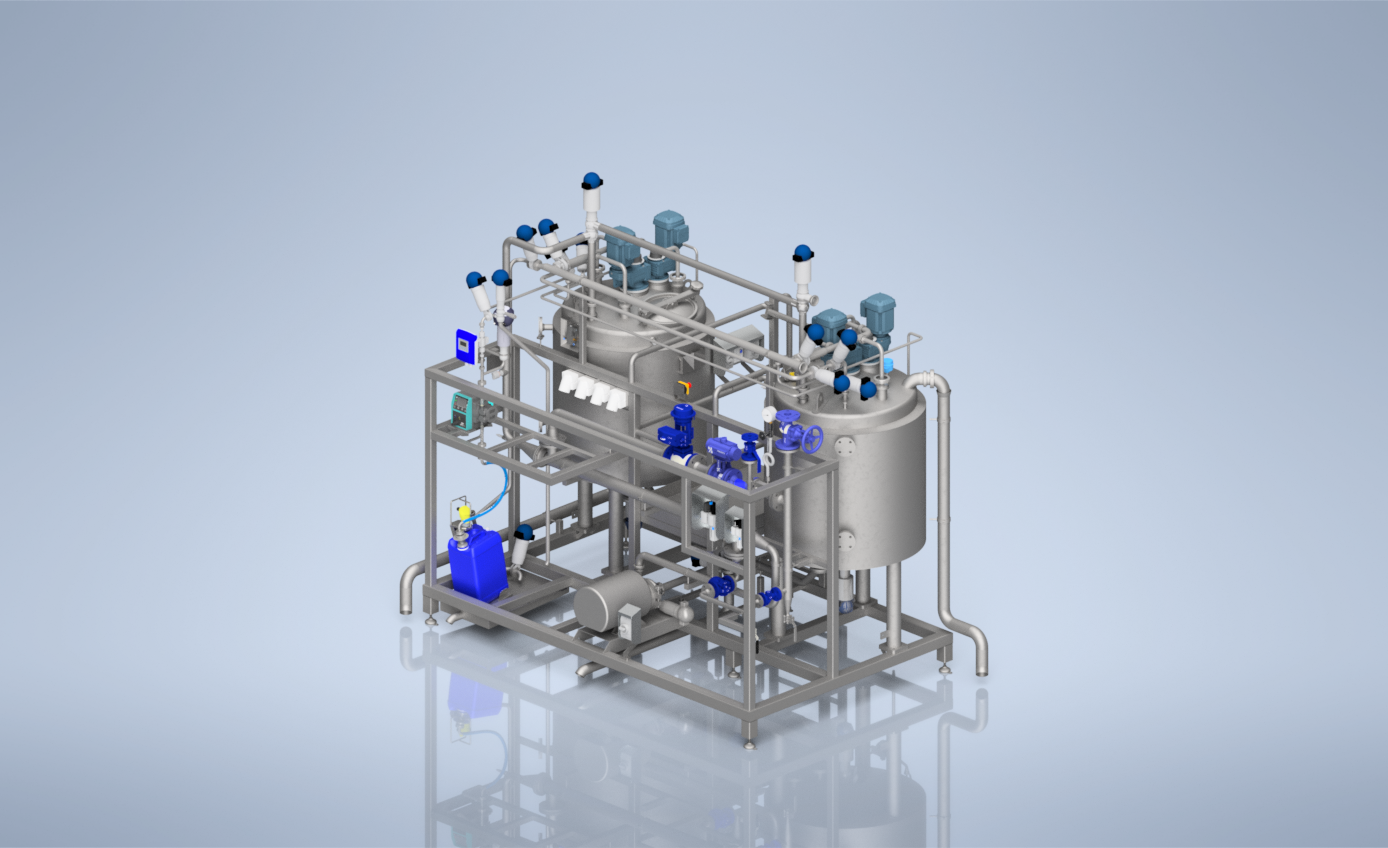

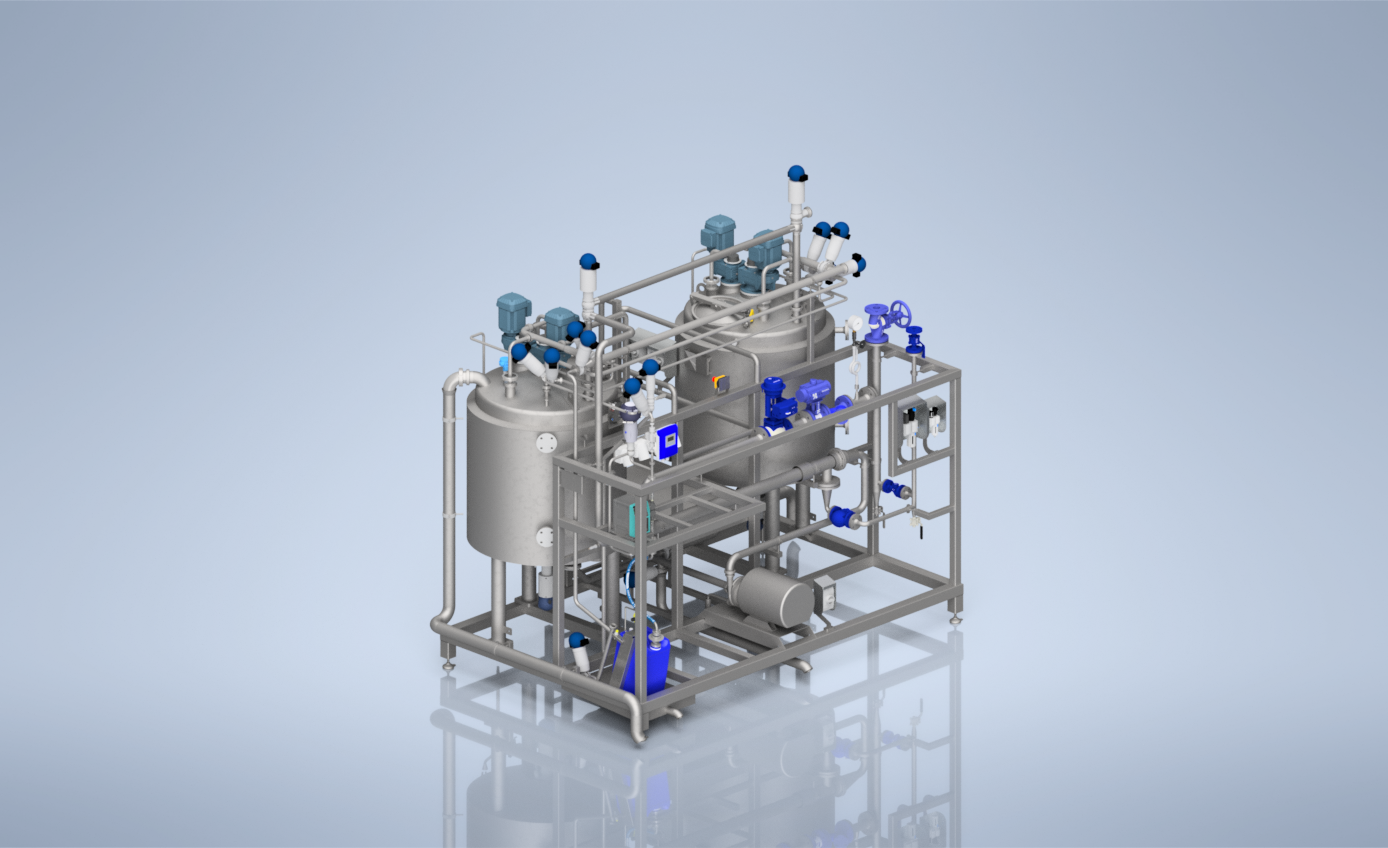

FlowMix System

Customized agitation for optimal liquid mixing

Description

Application

Batch mixing systems are the heart of fluid processing, ensuring that low to medium viscosity liquid products are perfectly mixed. Achieving homogeneity is critical to product quality, regardless of the industry. At D&W, our batch mixing systems are designed to deliver consistent and homogeneous products that meet the diverse needs of different applications. This application is of utmost importance to industries where product quality, uniformity and precision are critical.

Concept

At D&W, our batch mixing systems are based on a concept that revolves around the nuanced art of agitation. We recognize that every liquid product can have different mixing requirements – some require gentle mixing without dispersion, while others may benefit from controlled dispersion for optimum consistency. Our systems are designed to accommodate these variations by utilizing a variety of agitator types. From high shear agitators for dispersion to propeller agitators for gentle mixing, we tailor the agitator selection to the specific requirements of each application. This approach ensures that each product is mixed to its unique needs and delivers homogeneity without compromise.

Working principle

Our FlowMix system consists of a stainless steel tank as standard, which is equipped with one or more agitators. The type and number of agitators depends on the product application. By means of manual or automated dosing systems, the liquids are introduced into the tank based on a recipe and it can be determined – very precisely – per recipe line what the agitation behavior should be in order to obtain the right product consistency and homogeneity. Optionally, our system can be equipped with a heating or cooling system to heat or cool the product during the mixing phase. The technology we use guarantees that each liquid product is processed with precision, resulting in a homogeneous product of high quality that meets the intended characteristics and specifications.

Additive dosing

This system is often equipped with CIP cleanable dosing stations for adding small additives under hygienic conditions.

Details

Base unit

This unit consists of a base module which is positioned on a fixed frame. The base module consists of, among other things:

- A stainless steel batch tank

- One or more agitators

- Various instrumentation

- Various valves

Automation

Our units are controlled by a Siemens PLC as standard. This is installed in a stainless steel control cabinet on the unit. On request, an Allen Bradley ControlLogix can also be applied. Operation is via an HMI panel mounted on the control cabinet. The HMI panel visualises a clear program with a large number of adjustable parameters and settings.

Optional

- Integrated heating circuit

- Integrated cooling circuit

- Integrated CIP functionality

Options are not included

Data

Technical

Consumption

Curious about what we can do for you?

Then contact us now!